There are different types of pipe flanges used in the piping systems depending upon the fluid, PT rating, material of construction, connecting equipment etc.

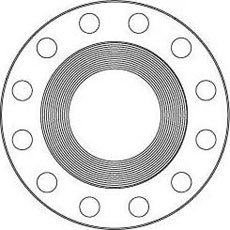

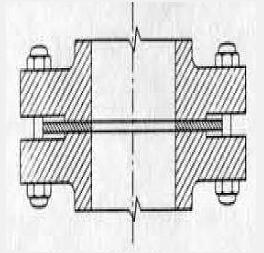

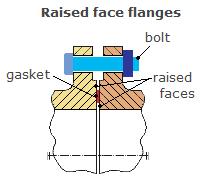

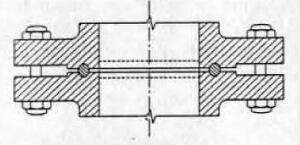

These pipe flanges are the most commonly used flanges. The raised face thickness for 150# and 300# are included in the specified flange thickness and for higher rating they are not included in the flange thickness.

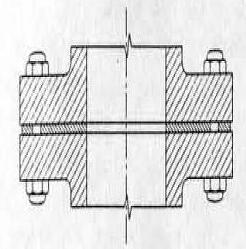

These pipe flanges are used when the counter flanges are flat face. They are mainly used at connection to cast iron equipment, valves and specialties. This flat face flange has a gasket surface in the same plane as the bolting circle face.

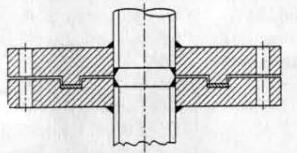

These pipe flanges are most reliable type of flange joint but are costlier than the other type of flanges.

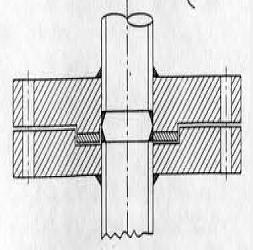

The Ring Type Joint flanges are generally used in high pressure (Class 600 and higher rating) and/or high temperature services above 800°F (427°C).

These pipe flanges are most reliable type of flange joint but are costlier than the other type of flanges.

These pipe flanges are better version of Raised face flanges.

The raised face, RF, is the standard process connection on our third party seals and thermowells. Both have options for a RTJ and FF type flange connections. The Raised Face (RF) is the most common type used in process plant applications.

The gasket surface of the flange is raised above the bolting circle face. A Ring-type Joint (RTJ) can also have a raised gasket face with the difference being the ring groove machined in this face.

This groove will accommodate a steel ring gasket for flange mating. The Flat Face, FF, flange has a gasket surface that is in the same plane as the bolting circle face.

None of these three flange types are interchangeable between types, i.e. RTJ flange cannot be mated to a RF flange.

Requirements are valid for normal case, in special case you have to contact the technical department.

Below you will find a short description and definition of each type, completed with an detailed image.