我们接下来检查生产电阻焊接(ERW)管所需的基本步骤。

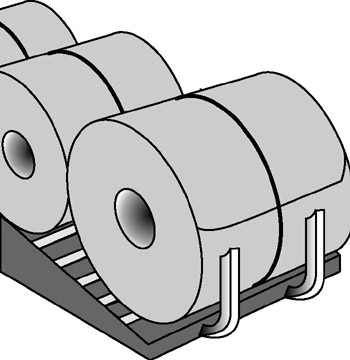

将线圈从储存中取出并放置在进料斜坡上(参见图4.1)。每个线圈被送入未磁性单元。

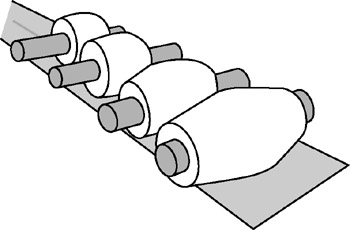

The roll transition section receives the product from the first forming section and continues the "rounding-up" process .

This section of the forming rolls finishes the rounding process and prepares the edges of the strip for welding .

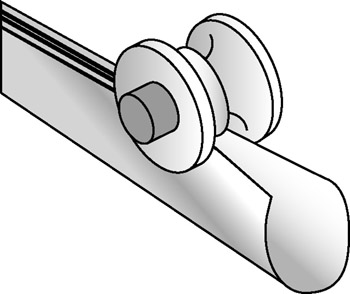

自动高频焊机将条带的边缘加热到融合点位置的大约2600f。

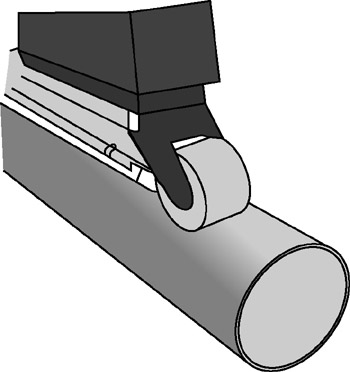

Pressure rollers squeeze these heated edges together to form a fusion weld.

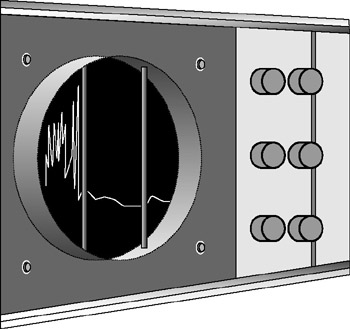

After welding has been completed, it is inspected by independent nondestructive inspection units.

然后将焊接区域经过焊接处理,作为金属物质所需的焊接处理,以除去残留的焊接应力并产生均匀的归一化晶粒结构。

管道通过浆磨机以达到铝铝合金的正确外部磨料。

The pipe is then cut to the correct length.

这通常是阶段的,其中管道末端面对并由末端的凹槽粘连。所有这些过程都是连续的自动布置。这些普通的端部管进一步用于根据客户要求进行加工,例如镀锌,螺纹,黑色漆等。

Welded steel pipe (steel pipe manufactured with a weld) is a tubular product made out of flat plates, known as skelp, that are formed, bent and prepared for welding.