金属膨胀接头(also called compensator) is compensating elements for thermal expansion and relative movement in pipelines, containers and machines.

对于遇到高压,高温和/或苛刻的化学物质的苛刻管和管道应用,金属膨胀接头是最安全,最可靠的解决方案。

High pressure, high temperature media and harsh and/or corrosive chemicals demand safe, reliable, and leak-free joints between pipe or duct sections. But, because no piping or ductwork system is perfectly designed, and because movement and vibration can’t be avoided in most (if not all) applications, you need a way to accommodate for these factors without damaging your system.

这就是我们的金属膨胀接头进入的地方。虽然它们没有作为橡胶或弹性体膨胀接头提供尽可能多的灵活性,但金属膨胀接头更适合挑战应用和危险介质。

Please keep these questions in mind when specifying the metal expansion joints you need:

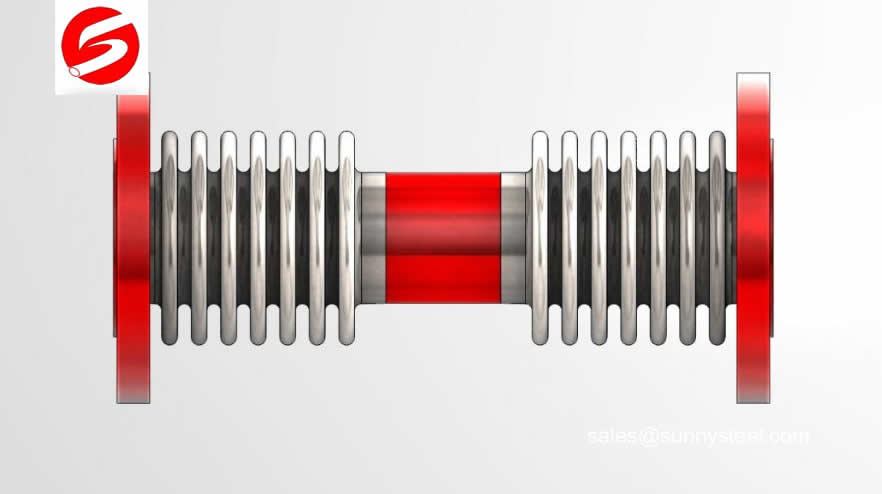

通用膨胀接头由两个与中间管连接的波纹管组成。安装在排气系统中的这种膨胀接头吸收轴向和横向的热膨胀,振动和压力运动。通用扩展关节是无限制的,它们具有低压系统的应用。

通用膨胀接头由两个带有央行管道的波纹管组成 - 这可以用法兰或管道提供。与单个膨胀接头相比,这些接头设计用于吸收更大的轴向和横向运动。中央管长度的增加越长,波纹管可以吸收横向偏转。

The universal expansion joint can absorb not only axial movements but angular and lateral movements as well. It consists of two metal bellows with an intermediate pipe and connectors on both sides.

作为轴向膨胀接头的特殊形式,通用伸缩接头仅具有限制性的耐压性,而且载入由内部压力产生的轴向压缩力的相邻管道支撑。

The universal metal expansion joints are usually used to compensate large axial and lateral movements at low pressure.

通用膨胀接头由连通管道或中心连接的两个波纹管组成。这种类型的组装允许三种基本运动的任何组合:轴向,横向和角度。通用伸缩节通常用于比单个轴向膨胀接头吸收更多的横向运动的情况,或者当连接管系统允许的量横向力有限制时。E Universal膨胀接头的横向移动能力取决于中心展示。当使用通用膨胀接头时,锚点必须符合稳定的全推力。

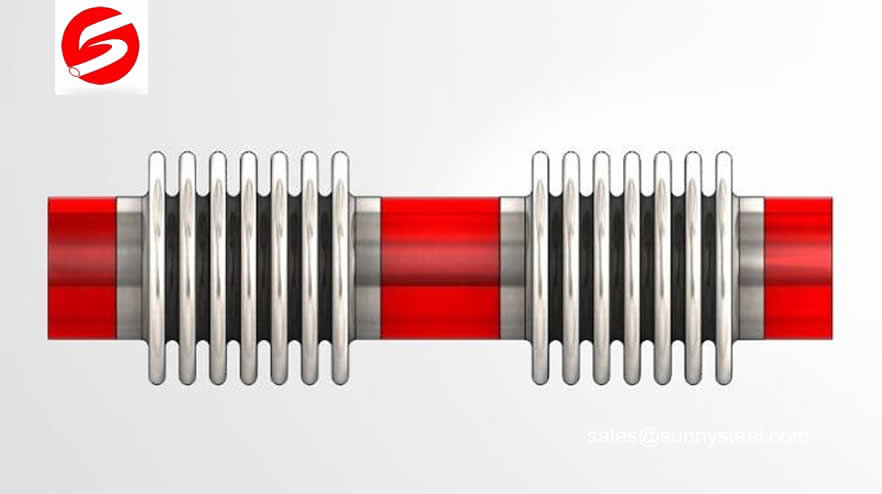

捆绑通用膨胀节

通常,LN更高的压力应用,连接管系统可以容纳的力的限制。这些情况可以使用捆绑的通用膨胀节。R〜E棒限制压力推力,同时允许大量的横向运动。使用没有拉杆的通用膨胀接头吸收的横向运动的量取决于中心池长度。拉杆不允许膨胀接头吸收粘合长度外部的任何轴向延伸部。对于管道配置不允许将绑定的通用扩展孔隙压缩来压缩。因此,这将减轻拉杆张力,从而允许压力推力在管道系统上采用。

Tied universal expansion joints are frequently used to absorb lateral deflection in a “Z” bend configuration. The expansion joint absorbs the thermal movement ol horizontal pipelines as lateral defleclion. This can be accomplished in a single plane or three plane configuration. In a three plane “Z ” bend the horizontal pipes may lie at any angle in the horizontal plane since the tied universal expansion joint can absorb lateral deflection in any direction.

| 名义直径(mm) | Quantity of ripple | Pressure level | Effective area of corrugated tube(cm2) | Maximum external diameter |

||||

|---|---|---|---|---|---|---|---|---|

| 0.25 | 0.6 | 1.0 | 1.6 | 2.5 | ||||

Axial compensation |

刚性 (N/mm) |

Axial compensation |

Length(mm) | 韧性 |

||||

| 32 | 8. | 25/21 | 22/26 | 20/26 | 18/63 | 16 | 225 | |

| 32 | 16 | 50/11 | 4.6./14 | 41/14 | 36/32 | 16 | 225 | |

| 4.0 | 8. | 25/28 | 22/44 | 20/44 | 18/89 | 15/98 | 23 | 244 |

| 4.0 | 16 | 50/14 | 4.6./22 | 4.1/22 | 36/45 | 31/47 | 23 | 244 |

| 5.0 | 8. | 25/30 | 22/51 | 20/70 | 18/70. | 15/106 | 37 | 259 |

| 5.0 | 16 | 50/16 | 4.6./26 | 4.1/35 | 36/35 | 31/55 | 37 | 259 |

| 6.5. | 8. | 33/28 | 30/35 | 26/44 | 22/55 | 15/138 | 5.5. | 270 |

| 6.5. | 12 | 42/16 | 38/22 | 38/32 | 34/40 | 31/70 | 5.5. | 270 |

| 8.0 | 8. | 40/20 | 36/26 | 34/33 | 28/41 | 19/68 | 8.1 | 284 |

| 8.0 | 10 | 53/14 | 4.9./17 | 49/21 | 43/26 | 29/50 | 8.1 | 284 |

| 100 | 6. | 4.5./47 | 4.5./60 | 40/75 | 35/93 | 25/54 | 121 | 304. |

| 100 | 10 | 76/26. | 74/32 | 64/40 | 5.7/50 | 38/33 | 121 | 304. |

| 125 | 5. | 4.8./38 | 42/47 | 38/59. | 34/74 | 29/117 | 180 | 334 |

| 125 | 9. | 8.5./23 | 77/29 | 6.6./36 | 5.8./45 | 49/63 | 180 | 334 |

| 150 | 5. | 49/42 | 4.4/50 | 4.0/62 | 34/78 | 29/92 | 257 | 364 |

| 150 | 8. | 79/34 | 71/43 | 64/51 | 5.4/59 | 50/56 | 257 | 364 |

| 200 | 4. | 52/49 | 4.6./55 | 42/68 | 38/78 | 29/97 | 4.79 | 4.42 |

| 200 | 6. | 73/31 | 65/44 | 5.9./52 | 53/58 | 4.6./65 | 4.79 | 4.42 |

| 250 | 4. | 72/30 | 65/34. | 5.9./42 | 52/45 | 34/111 | 769. | 507. |

| 250 | 6. | 108/16 | 9.7/21 | 87/35 | 79/39 | 48/78 | 769. | 507. |

| 300 | 4. | 72/51 | 65/55. | 5.9./59 | 52/65. | 4.7/55 | 1105. | 5.6.2 |

| 300 | 6. | 108/32 | 9.7/35 | 87/37 | 79/41 | 71/47 | 1105. | 5.6.2 |

| 350 | 4. | 72/58 | 6.5./62 | 59/67 | 52/74 | 4.7/71 | 1307 | 622. |

| 350 | 6. | 108/38 | 87/41 | 87/44 | 79/48 | 71/45 | 1307 | 622. |

| 400 | 4. | 72/54. | 6.5./68 | 59/62 | 52/68 | 47/81 | 1611 | 700. |

| 400 | 6. | 108/36. | 9.7/39 | 87/43 | 79/47 | 71/47 | 1611 | 700. |

| 4.5.0 | 4. | 108/32 | 9.7/35 | 87/37 | 79/41 | 4.7/75 | 1972 | 760. |

| 4.5.0 | 6. | 162/20 | 145/22 | 131/23 | 118/25 | 71/52 | 1972 | 760. |

| 500. | 4. | 108/59. | 97/64 | 87/68 | 79/75 | 71/45 | 2445. | 835. |

| 500. | 6. | 162/34 | 145/37 | 131/39 | 118/43 | 106/28 | 2445. | 835. |

| 600 | 4. | 108/74 | 97/80 | 8.7/85 | 79/94 | 71/82 | 3534. | 980. |

| 600 | 6. | 162/42 | 145/45 | 131/49 | 118/53 | 106/48 | 3534. | 980. |

| 700. | 4. | 108/67 | 97/72 | 87/77 | 79/85 | 71/103 | 4.717 | 1110. |

| 700. | 6. | 162/42 | 145/45 | 131/49 | 118/53 | 106/60 | 4.717 | 1110. |

| 800 | 4. | 120/88 | 108/95 | 102/102 | 94/112 | 71/95. | 5822 | 1265. |

| 800 | 6. | 183/67 | 164/72 | 156/77 | 144/85 | 106/60 | 5822 | 1265. |

| 9.00 | 4. | 120/84 | 108/90 | 102/97 | 94/107 | 82/123 | 7620. | 1186. |

| 9.00 | 6. | 183/60 | 164/65 | 156/69 | 144/76 | 125/93 | 7620. | 1186. |

| 1000 | 4. | 120/91 | 108/98 | 102/105 | 94/116 | 8.2/117 | 9.043 | 1286. |

| 1000 | 6. | 183/59 | 164/65 | 156/71 | 144/81 | 125/84 | 9.043 | 1286. |

Datas above are only for reference, pls contact us for exact datas and price!

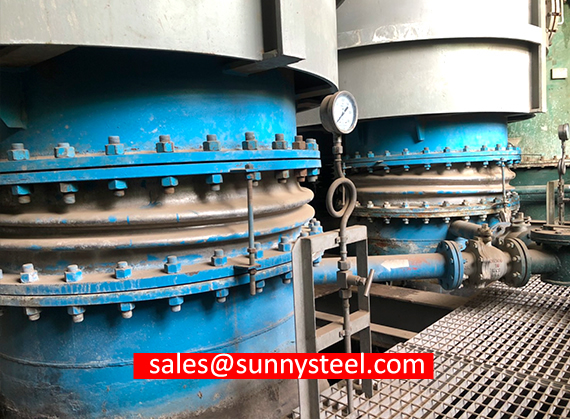

Installing product: Metal expansion joint with carbon steel flange

Size: DN1600 DN1200

Inner package of bellow expansion joint

plastic bag + carton cases one pcs/box

Outer package of bellow expansion joint

木箱子

各种材料采用不同品种的管配件,可以各种形状和尺寸提供。

Our team is highly trained and experienced in servicing and producing all types of steel supplies.