DIN Flanges production and processing of finished solution treatment must be enclosed , so that product performance is optimal.

At Sunny Steel Factory owned pneumatic marking machine, all flanges are available to customers free typing products, customers can be requested marked material, pressure , caliber, production standards or customer to provide own special text.

| Flange Nominal Diameter | Pressure Rating (PN) | |||||

|---|---|---|---|---|---|---|

| **Nominal BSP Pipe Size | PN6 | PN10 | PN16 | PN25 | PN40 | |

| DN 10 | 75 | 90 | 90 | 90 | 90 | O.D. |

| 3/8" | 50 | 60 | 60 | 60 | 60 | PCD (bolt circle) |

| 4 x 11 | 4 x 14 | 4 x 14 | 4 x 14 | 4 x 14 | # of holes x diam. of holes | |

| DN 15 | 80 | 95 | 95 | 95 | 95 | O.D. |

| 1/2" | 55 | 65 | 65 | 65 | 65 | PCD (bolt circle) |

| 4 x 11 | 4 x 14 | 4 x 14 | 4 x 14 | 4 x 14 | # of holes x diam. of holes | |

| DN 20 | 90 | 105 | 105 | 105 | 105 | O.D. |

| 3/4" | 65 | 75 | 75 | 75 | 75 | PCD (bolt circle) |

| 4 x 11 | 4 x 14 | 4 x 14 | 4 x 14 | 4 x 14 | # of holes x diam. of holes | |

| DN 25 | 100 | 115 | 115 | 115 | 115 | O.D. |

| 1" | 75 | 85 | 85 | 85 | 85 | PCD (bolt circle) |

| 4 x 11 | 4 x 14 | 4 x 14 | 4 x 14 | 4 x 14 | # of holes x diam. of holes | |

| DN 32 | 120 | 140 | 140 | 140 | 140 | O.D. |

| 11/4" | 90 | 100 | 100 | 100 | 100 | PCD (bolt circle) |

| 4 x 14 | 4 x 18 | 4 x 18 | 4 x 18 | 4 x 18 | # of holes x diam. of holes | |

| DN 40 | 130 | 150 | 150 | 150 | 150 | O.D. |

| 11/2" | 100 | 110 | 110 | 110 | 110 | PCD (bolt circle) |

| 4 x 14 | 4 x 18 | 4 x 18 | 4 x 18 | 4 x 18 | # of holes x diam. of holes | |

| DN 50 | 140 | 165 | 165 | 165 | 165 | O.D. |

| 2" | 110 | 125 | 125 | 125 | 125 | PCD (bolt circle) |

| 4 x 14 | 4 x 18 | 4 x 18 | 4 x 18 | 4 x 18 | # of holes x diam. of holes | |

| DN 65 | 160 | 185 | 185 | 185 | 185 | O.D. |

| 2 1/2" | 130 | 145 | 145 | 145 | 145 | PCD (bolt circle) |

| 4 x 14 | 4 x 18 | 4 x 18 | 8 x 18 | 8 x 18 | # of holes x diam. of holes | |

| DN 80 | 190 | 200 | 200 | 200 | 200 | O.D. |

| 3" | 150 | 160 | 160 | 160 | 160 | PCD (bolt circle) |

| 4 x 18 | 8 x 18 | 8 x 18 | 8 x 18 | 8 x 18 | # of holes x diam. of holes | |

| DN 100 | 210 | 220 | 220 | 235 | 235 | O.D. |

| 4" | 170 | 180 | 180 | 190 | 190 | PCD (bolt circle) |

| 4 x 18 | 8 x 18 | 8 x 18 | 8 x 22 | 8 x 22 | # of holes x diam. of holes | |

| DN 125 | 240 | 250 | 250 | 270 | 270 | O.D. |

| 5" | 200 | 210 | 210 | 220 | 220 | PCD (bolt circle) |

| 8 x 18 | 8 x 18 | 8 x 18 | 8 x 26 | 8 x 26 | # of holes x diam. of holes | |

| DN 150 | 265 | 285 | 285 | 300 | 300 | O.D. |

| 6" | 225 | 240 | 240 | 250 | 250 | PCD (bolt circle) |

| 8 x 18 | 8 x 22 | 8 x 22 | 8 x 26 | 8 x 26 | # of holes x diam. of holes | |

| DN 175 | 315 | 315 | 330 | 350 | O.D. | |

| 7" | 270 | 270 | 280 | 295 | PCD (bolt circle) | |

| 8 x 22 | 8 x 22 | 12 x 26 | 12 x 30 | # of holes x diam. of holes | ||

| DN 200 | 320 | 340 | 340 | 360 | 375 | O.D. |

| 8" | 280 | 295 | 295 | 310 | 320 | PCD (bolt circle) |

| 8 x 18 | 8 x 22 | 12 x 22 | 12 x 26 | 12 x 30 | # of holes x diam. of holes | |

| DN 250 | 375 | 395 | 405 | 425 | 450 | O.D. |

| 10" | 335 | 350 | 355 | 370 | 385 | PCD (bolt circle) |

| 12 x 18 | 12 x 22 | 12 x 26 | 12 x 30 | 12 x 33 | # of holes x diam. of holes | |

| DN 300 | 440 | 445 | 460 | 485 | 515 | O.D. |

| 12" | 395 | 400 | 410 | 430 | 450 | PCD (bolt circle) |

| 12 x 22 | 12 x 22 | 12 x 26 | 16 x 30 | 16 x 33 | # of holes x diam. of holes | |

| DN 350 | 490 | 505 | 520 | 555 | 580 | O.D. |

| 14" | 445 | 460 | 470 | 490 | 510 | PCD (bolt circle) |

| 12 x 22 | 16 x 22 | 16 x 26 | 16 x 33 | 16 x 36 | # of holes x diam. of holes | |

| DN 400 | 540 | 565 | 580 | 620 | 660 | O.D. |

| 16" | 495 | 515 | 525 | 550 | 585 | PCD (bolt circle) |

| 16 x 22 | 16 x 26 | 16 x 30 | 16 x 36 | 16 x 39 | # of holes x diam. of holes | |

| DN 500 | 645 | 670 | 715 | 730 | 755 | O.D. |

| 20" | 600 | 620 | 650 | 660 | 670 | PCD (bolt circle) |

| 20 x 22 | 20 x 26 | 20 x 33 | 20 x 36 | 20 x 42 | # of holes x diam. of holes | |

| DN 600 | 755 | 780 | 840 | 845 | O.D. | |

| 24" | 705 | 725 | 770 | 770 | PCD (bolt circle) | |

| 20 x 24 | 20 x 27 | 20 x 33 | 20 x 36 | # of holes x diam. of holes | ||

All the Raw Materials received by our company are subject to chemical and physical test and weighed immediately on receipt only thereafter they are taken in the stock.

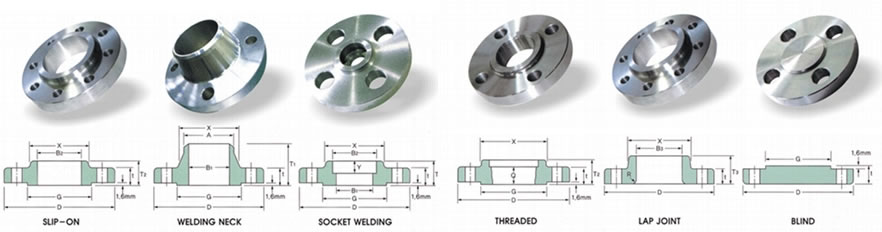

The Welding neck flanges is normally referred to as the high hub flange.

A weld neck flange (also known as a high-hub flange and tapered hub flange) is a type of flange.

Threaded flanges are widely demanded as pipe flanges i.e called as threaded pipe flanges used in different industrial applications.

Slip-On flanges or SO flanges are commonly lower in price than weld-neck flanges, and to this effect are a popular choice for our customers.

The blind flange is used to close ends of piping systems. It is a kind of round plate with no center hold but with all the proper bolt holes.

In many applications, engineers need to find a way to close off a chamber or cylinder in a very secure fashion, usually because the substance inside must differ from the substance outside in composition or pressure.

DIN Flanges production and processing of finished solution treatment must be enclosed , so that product performance is optimal.

Both the AWWA and ANSI have thorough standards for flanges, and the two standards are different in several ways.

Requirements are valid for normal case, in special case you have to contact the technical department.

Below you will find a short description and definition of each type, completed with an detailed image.

Our team is highly trained and experienced in servicing and producing all types of steel supplies.