ASTM A420 WPL6年级与ASTM A420相关联for pipe fittings manufactured of Wrought Carbon Steel.

ASTM A420 / A420M-07用于低温服务的锻炼钢和合金钢管道配件的标准规范。WPL6是碳钢的标准化等级,在-50度F中测试的夏比冲击用于低温服务。另见Flanges还参见ASTM A333等级1和6(管道)和A350 LF2。

ASTM A420 WPL6 Elbow after complete quality and performance measure inspection. These are widely appreciated for excellent quality, corrosion abrasion and high tensile strength with long life service.

材料s shall consist of forgings, bars, plates, seamless or fusion welded tubular products with filler metal added, and shall be produced by open-hearth, basic-oxygen, or electric-furnace process. Forging or forming operations shall be performed by one or a combination of two or more of the following procedures: hammering, pressing, piercing, extruding, upsetting, working, bending, fusion-welding, or machining. All welding shall be completed prior to the austenitizing heat treatment, which shall be executed in the normalized, normalized and tempered, annealed, or quenched and tempered conditions. Steel specimens shall conform to required values of chemical composition, tensile strength, yield strength, elongation, wall thickness, and Charpy V-notch impact value. All fusion-welded butt joints shall undergo radiographic examination, while hydrostatic testing of fittings is not required in this specification. Repair welding shall be permissible for parts made to dimensional standards.

This abstract is a brief summary of the referenced standard. It is informational only and not an official part of the standard; the full text of the standard itself must be referred to for its use and application. ASTM does not give any warranty express or implied or make any representation that the contents of this abstract are accurate, complete or up to date.

1.1本规范涵盖锻造碳钢和合金钢配件无缝和焊接结构,由ASME B16.9,ASME B16.11,MSS SP-83,MSS SP-95和MSS的最新版本覆盖SP-97。与这些ASME和MSS标准不同的配件,应根据规格A960 / A960M的补充要求S58提供。这些配件用于低温下的压力管道和压力容器服务。

1.2 Optional supplementary requirements are provided for fittings where a greater degree of examination is desired. When desired, one or more of these supplementary requirements shall be specified in the order.

1.3本规范以英寸为单位和SI单元表示。但是,除非订单指定适用的“M”规格指定(SI单位),否则材料应为英寸磅单位提供。

1.4 SI单位或英寸磅单元中所述的值将被单独视为标准。在文中,SI单位显示在括号中。每个系统中所述的值可能不是精确的等价物;因此,每个系统应独立使用。组合来自两个系统的值可能导致与标准不符。

ASTM A420的化学成分(%)

| 年级 | C | MN. | P | S | Si |

| WPL6(1)(2) | 0.3 | 0.60-1.35 | 0.035 | 0.04 | 0.15-0.30 |

| WPL9 | 0.2 | 0.40-1.06 | 0.03 | 0.03 | - |

| 年级 | 你 | Cu | Cr | 莫 | V | NB. |

| WPL6(1)(2) | 0.4 | 0.4 | 0.3 | 0.12 | 0.08 | 0.02 |

| WPL9 | 1.60-2.24 | 0.75-1.25 | - | - | - | - |

一般注意事项:

All values are maximum unless otherwise indicated.

NOTES:

(1)对于每次减少0.01%C以下0.30%,允许增加0.05%以上1.06%,最大为1.35%。

(2)由锻件制成的配件可具有1.35%MAX MN。

ASTM A420的机械性能

| 拉伸要求 | WPL6 | WPL9 |

| Tensile Strength min, ksi [MPa] |

60-85 [415-585] | 63-88 [435-610] |

| 屈服强度 min, ksi [MPa] |

35 [240] | 46 [315] |

在壁厚位于上述两个值之间,最小伸长值由以下等式确定:

影响测试属性

由于这些管件主要用于低温服务,因此必须考虑夏比V-intch冲击试验的特性。

Charpy Impact Requirements for WPL6, WPL9, and WPL3

| 标本的大小 | A* | B* | ||

| 毫米 | FT·LBF. | J | FT·LBF. | J |

| 10到10.0 | 13 | 17.6 | 10 | 13.6 |

| 10 by 7.5 | 10 | 13.6 | 8 | 10.8 |

| 10 by 5.0 | 7 | 9.5 | 5 | 7.0 |

| 10乘2.5 | 4 | 5.4 | 3 | 4.1 |

A * Charpy V-Notch撞击值所需的接受(三个标本的平均值)

B *最小夏比V-intch撞击值,不需要重新测试(仅为一个标本,只有一个标本)WPL8的Charpy Impact要求

| 标本的大小 | A* | B* | ||

| 毫米 | FT·LBF. | J | FT·LBF. | J |

| 10到10.0 | 25.0 | 33.9 | 20.0 | 27.1. |

| 10 by 7.5 | 21.0 | 28.5 | 17.0 | 23.1. |

| 10 by 5.0 | 17.0 | 23.1. | 14.0 | 19.0 |

| 10乘2.5 | 8.0 | 10.8 | 6.0 | 8.1 |

A * Charpy V-Notch撞击值所需的接受(三个标本的平均值)

B *最小Charpy V-Notch撞击值,无需重新测试(仅为一个标本)

冲击试验温度

| 年级 | °F [°C] |

| WPL6 | −50 [−45] |

| WPL9 | -100 [-75] |

| WPL3 | -150 [-100] |

| WPL8 | -320 [-195] |

材料和制造

The raw material for these fittings shall be fully killed steel, consisting of forgings, bars, plates, sheet, and seamless or fusion welded tubular products(pipes, tubes, or cylinders).

Heat Treatment

All fittings shall be furnished in the normalized, normalized and tempered, annealed, or quenched and tempered condition. All welding shall be completed prior to the austenitizing heat treatment. After forming, the fittings shall be allowed to cool below the lower critical before applying one of the heat treatments. When specified, post-weld heat treatment may be required.

产品和标准

Tests and Inspections

Pipe fittings manufactured to ASTM A420 shall take the following tests or inspections: dimensional inspection, visual examination, hydrostatic test(when required), chemical analysis, tensile test, impact test, radiographic test(RT).

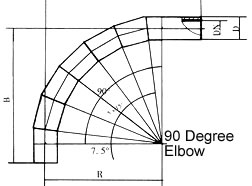

弯头是安装在两个长度的管道或管道之间的管道,以允许方向的变化,通常是180°或90°角,但也制造45°弯头。可以为对接焊接(SW)或插座焊接(SW)等加工端部。

大多数肘部都有短半径或长半径变体。当两端尺寸的尺寸不同时,配件称为还原弯头或减速器弯头。

肘部根据以下各种设计特征进行分类:

材料s

SHS-self-propagating ceramic composite steel pipe and fittings, the new generation of wearable and corrosion resistant engineering pipeline, belongs to "863" Hi-tech Plan products.

SHS-self-propagating ceramic composite steel pipe and fittings, the new generation of wearable and corrosion resistant engineering pipeline, belongs to "863" Hi-tech Plan products.它是理想的可穿戴和耐腐蚀的工程管道,耐磨性高于普通钢管,内表面光滑和良好的液体抗性。

管肘的应用:

石油,化工,电源,天然气,冶金,造船,施工等。

ELL & ELLS

There are different varieties of pipe fittings made of various materials and available in various shapes and sizes.