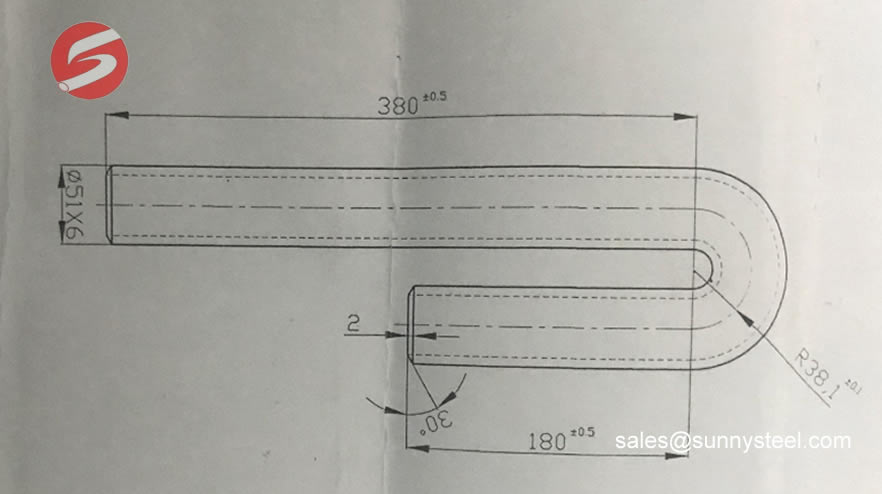

We bend SA 213-T22 u-bend tube with round, rectangular, square, plus oval cross sections used in medical, automotive, plus electronics industries.

Chemical Composition(%) for ASTM A213 T22 Low Alloy Steel

| UNS Designation | K21590 |

| Carbon | 0.05-0.15 |

| Manganese | 0.30–0.60 |

| Phosphorus | 0.025 |

| Sulfur | 0.025 |

| Silicon | 0.50 |

| Nickel | … |

| Chromium | 1.90-2.60 |

| Molybdenum | 0.87-1.13 |

| Vanadium | … |

| Boron | … |

| Niobium | … |

| Nitrogen | … |

| Aluminum | … |

| Tungsten | … |

| Other Elements | … |

Mechanical properties for ASTM A213 T22 Low Alloy Steel

| Tensile strength(min) | 415Mpa |

| Yield strength(min) | 220Mpa |

| Elongation | 30% |

| Delivery condition | annealed |

We are passionate about pipe bending:

弯头、弯管、管bending, ANSI, ISO, JIS and DIN Standards, Measures 1/2 to 56 Inches.

The bend is used to change the direction of run of pipe.it advantage is can matach long distance transition requirements,so it is commonly that bends dimension according to customer design. usually,the bends consist of3D,5D,7Dand12Dseries.

Key Specifications/Special Features:

End bevel:according to the bevel of welding pipe fittings construction all the size can product according to the clients' requiry.

Standard:

Pressure:SCH5 to SCH160Bending radius(R): R=3D,5D,7Dand12D

Bending angle (θ):15°, 30°, 45°, 60°, 90°, 135°,180°

Outer diamete(D): D≤1800mm

Wall thickness(T): T≤120mm

Straight Length (L): The length between two ends general from 300mm-1500mm

Materials

Industrial Processes

Bending, squeezing, pressing, forging, machining and more

Our team is highly trained and experienced in servicing and producing all types of steel supplies.