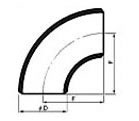

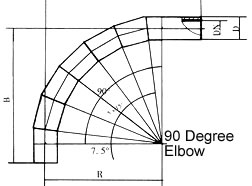

SA335 P91 elbow is curved connecting pieces that join straight lengths of pipe, commonly at a 90° or 45° angle, allowing obstructions to be avoided in plumbing, ventilation, welding, and automotive applications.

ASTM A335 P91 is the part of ASTM A335, The pipe shall be suitable for bending, flanging, and similar forming operations, and for fusion welding.

The steel material shall conform to chemical composition, tensile property, and hardness requirements.

An elbow is a pipe fitting installed between two lengths of pipe or tubing to allow a change of direction, usually a 180° or 90° angle, though 45° elbows are also made. The ends may be machined for butt welding (SW) or socketed welding(SW) etc.

大多数肘部在短半径或长radius variants. When the two ends differ in size, the fitting is called a reducing elbow or reducer elbow.

Elbows are categorized based on various design features as below:

材料

SHS-self-propagating ceramic composite steel pipe and fittings, the new generation of wearable and corrosion resistant engineering pipeline, belongs to "863" Hi-tech Plan products.

SHS-self-propagating ceramic composite steel pipe and fittings, the new generation of wearable and corrosion resistant engineering pipeline, belongs to "863" Hi-tech Plan products.It is the ideal wearable and corrosion resistant engineering pipeline, with wear resistance 15 times higher than common steel pipe, smooth inner surface, and favorable liquor resistance.

Application of pipe elbows:

Petroleum, chemical, power, gas, metallurgy, shipbuilding, construction, etc.

ELL & ELLS

There are different varieties of pipe fittings made of various materials and available in various shapes and sizes.

Our team is highly trained and experienced in servicing and producing all types of steel supplies.