ASME B16.9 Standard covers overall dimensions, tolerances,ratings, testing, and markings for factory-made wrought buttwelding fittings in sizes NPS 1⁄2 through NPS 48 (DN 15 through DN 1200).

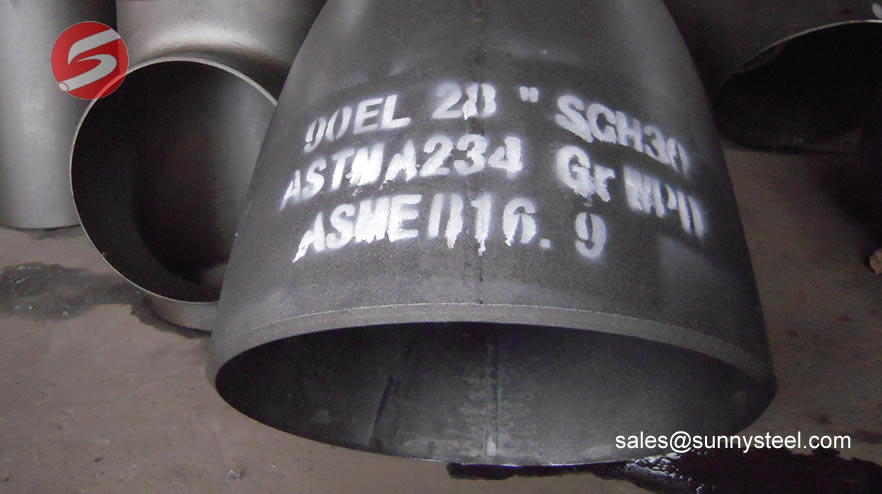

ASME B16.9 Large diameter elbow

ASME B16.9 Large diameter elbow

ASME B16.9 Standard covers overall dimensions, tolerances,ratings, testing, and markings for factory-made wrought buttwelding fittings in sizes NPS 1⁄2 through NPS 48 (DN 15 through DN 1200).

Factory-Made Wrought Buttwelding Fittings

ASME-American Society of Mechanical Engineers

36” x 26” STD SMLS/WLD BW ECCENTRIC REDUCER

ASTM A234 WP22 OR WP22W CL. 1

SCOPE

1.1 General

This Standard covers overall dimensions, tolerances,ratings, testing, and markings for factory-made wrought buttwelding fittings in sizes NPS 1⁄2 through NPS 48 (DN 15 through DN 1200).

1.2 Special Fittings

Fittings may be made to special dimensions, sizes,shapes, and tolerances by agreement between the manufacturer and the purchaser.

1.3 Fabricated Fittings

Fabricated laterals and other fittings employing circumferential or intersection welds are considered pipe fabrication and are not within the scope of this Standard.

Fabricated lap joint stub ends are exempt from the above restrictions, provided they meet all the requirements of the applicable ASTM material specification listed in section 5.

1.4 Standard Units

The values stated in either metric or U.S. Customary units are to be regarded separately as standard. Within the text, the U.S. Customary units are shown in parentheses.The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with this Standard.

The designation for size is NPS for both metric- and customary-dimensioned fittings. Fitting pressure rating is associated with the connecting wall thickness of pipe of equivalent size and material.

1.5 References

1.5.1 Referenced Standards. Standards and specifications adopted by reference in this Standard are shown in Mandatory Appendix II. It is not considered practical to identify the specific edition of each standard and specification in the individual references. Instead, the specific edition reference is identified in Mandatory Appendix II. A product made in conformance with a prior edition of referenced standards and in all other respects conforming to this Standard will be considered to be in conformance.

1.5.2 Codes and Regulations. A fitting used under the jurisdiction of the ASME Boiler and Pressure Vessel Code, the ASME Code for Pressure Piping, or a governmental regulation is subject to any limitation of that code or regulation. This includes any maximum temperature

limitation, or rule governing the use of a material at low temperature.

1.6 Service Conditions

Criteria for selection of fitting types and materials suitable for particular fluid service are not within the scope of this Standard.

1.7 Welding

Installation welding requirements are outside the scope of this Standard.

1.8 Quality Systems

Nonmandatory requirements relating to the fitting manufacturer’s Quality System Program are described in Nonmandatory Appendix A.

1.9 Convention

For the purpose of determining conformance with this Standard, the convention for fixing significant digits where limits (maximum or minimum values) are specified shall be rounded off as defined in ASTM E 29. This requires that an observed or calculated value shall be rounded off to the nearest unit in the last righthand digit used in expressing the limit. Decimal values and tolerances do not imply a particular method of measurement.

1.10 Pressure Rating Designation

Class, followed by a dimensionless number, is the designation for pressure–temperature ratings. Standardized designations for flanges per ASME B16.5 referenced in this Standard are Classes 150, 300, 600, 900, 1500,and 2500.

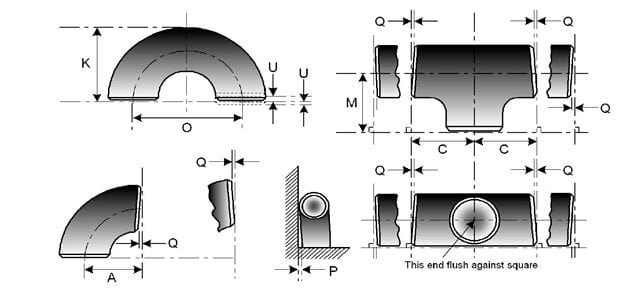

Pipe Fittings Dimensions Tolerance as per ASME B16.9:

大小s 1/2″ – 48″

ASME / ANSI B16.9维度

| Nominal Pipe 大小 |

Outside Diameter |

90° Elbows | 45° Elbows | 180° Returns | ||||

|---|---|---|---|---|---|---|---|---|

|

(inches)

|

Long Radius

|

Short Radius

|

Long Radius

|

Long Radius

|

||||

|

(mm)

|

(inches)

|

Center to Face (inches) |

Center to Face (inches) |

Center to Face (inches) |

Radius (inches) |

Center to Center (inches) |

Back to face (inches) |

|

|

1/2 |

21.3 |

0.840 |

1 1/2 |

– |

5/8 |

2 |

1 7/8 |

|

|

3/4 |

26.7 |

1.050 |

1 1/8 |

– |

7/16 |

2 1/4 |

1 11/16 |

|

|

1 |

33.4 |

1.315 |

1 1/2 |

1 |

7/8 |

3 |

2 3/16 |

|

|

1 1/4 |

42.2 |

1.660 |

1 7/8 |

1 1/4 |

1 |

3 3/4 |

2 3/4 |

|

|

1 1/2 |

48.3 |

1.900 |

2 1/4 |

1 1/2 |

1 1/8 |

3 |

4 1/2 |

3 1/4 |

|

2 |

60.3 |

2.375 |

3 |

2 |

1 3/8 |

4 |

6 |

4 3/16 |

|

2 1/2 |

73.0 |

2.875 |

3 3/4 |

2 1/2 |

1 3/4 |

5 |

7 1/2 |

5 3/16 |

|

3 |

88.9 |

3.500 |

4 1/2 |

3 |

2 |

6 |

9 |

6 1/4 |

|

3 1/2 |

101.6 |

4.000 |

5 1/4 |

3 1/2 |

2 1/4 |

7 |

10 1/2 |

7 1/4 |

|

4 |

114.3 |

4.500 |

6 |

4 |

2 1/2 |

8 |

12 |

8 1/4 |

|

5 |

141.3 |

5.563 |

7 1/2 |

5 |

3 1/8 |

10 |

15 |

10 5/16 |

|

6 |

168.3 |

6.625 |

9 |

6 |

3 3/4 |

12 |

18 |

12 5/16 |

|

8 |

219.1 |

8.625 |

12 |

8 |

5 |

12 |

24 |

16 5/16 |

|

10 |

273.1 |

10.750 |

15 |

10 |

6 1/4 |

15 |

30 |

20 3/8 |

|

12 |

323.9 |

12.750 |

18 |

12 |

7 1/2 |

18 |

36 |

24 3/8 |

| NOMINAL PIPE SIZE NPS | ANGULARITY TOLERANCES | ANGULARITY TOLERANCES |

|---|---|---|

| 大小 | Off Angle Q | Off Plane P |

| ½ to 4 | 0.03 | 0.06 |

| 5 to 8 | 0.06 | 0.12 |

| 10 to 12 | 0.09 | 0.19 |

| 14 to 16 | 0.09 | 0.25 |

| 18 to 24 | 0.12 | 0.38 |

| 26到30 | 0.19 | 0.38 |

| 32 to 42 | 0.19 | 0.50 |

| 44 to 48 | 0.18 | 0.75 |

艾尔L DIMENSIONS ARE GIVEN IN INCHES. TOLERANCES ARE EQUAL PLUS AND MINUS EXCEPT AS NOTED.

There are different varieties of pipe fittings made of various materials and available in various shapes and sizes.

Our team is highly trained and experienced in servicing and producing all types of steel supplies.